arduino cnc shield v3

Features:

- GRBL 0.8c compatible. (Open source firmware that runs on an Arduino UNO that turns G-code commands into stepper signals https://github.com/grbl/grbl)

- 4-Axis support (X, Y, Z , A-Can duplicate X,Y,Z or do a full 4th axis with custom firmware using pins D12 and D13)

- 2 x End stops for each axis (6 in total)

- Spindle enable and direction

- Coolant enable

- Uses removable Pololu A4988 compatible stepper drivers. (or DRV8825)

- Jumpers to set the Micro-Stepping for the stepper drivers. (max 1/16)

(The DRV8825 board can do up to 1/32 micro-stepping) - Stepper Motors can be connected with 4 pin molex connectors.

- Runs on 12-36V DC. (Only the Pololu DRV8825 can handle up to 36V)

Using two jumpers the 4th axis can be configured to clone the X or Y or Z axis. It can also run as an individual axis by using Digital Pin 12 for Stepping signal and Digital Pin 13 as direction signal. (GRBL only supports 3 axis’s at the moment)

Clone X-Axis to the 4th stepper driver(Marked as A)

Clone Y-Axis to the 4th stepper driver(Marked as A)

Clone Z-Axis to the 4th stepper driver(Marked as A)

Use D12 and D13 to drive the 4th stepper driver(Marked as A)

End Stop Configuration

By default GRBL is configured to trigger an alert if an end-stop goes low(Gets grounded). On the forums this has been much debated and some people requested to have active High end-stops. The jumpers in the picture provides the option to do both. (To run with default setting on GRBL the jumper need to be connected like the left shield in the image below)(This Jumper was only introduced in Version 3.02)

End-stop switches are standard “always open” switches. An End-stop gets activated when the end-stop pin connects to ground(When setup with default GRBL settings).

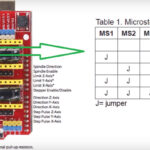

Configuring Micro Stepping for Each Axis

Each axis has 3 jumpers that can be set to configure the micro stepping for the axis.

In the tables below High indicates that a Jumper is insert and Low indicates that no jumper is inserted.